FLOW SHEET & MASS BALANCE

DUST SUPPRESSION SYSTEMS

SCRUBBER & WASHDOWN SYSTEMS

CHUTEWORK

BOILERS, CHILLERS, & COOLING TOWERS

COMPRESSED AIR

PROCESS STEAM AND UTILITY PIPING

PUMPS, SUMPS, & SLURRY

DUST COLLECTION & SUPPRESSION

At Ingenium Design we find the simple solution to save you time and money.

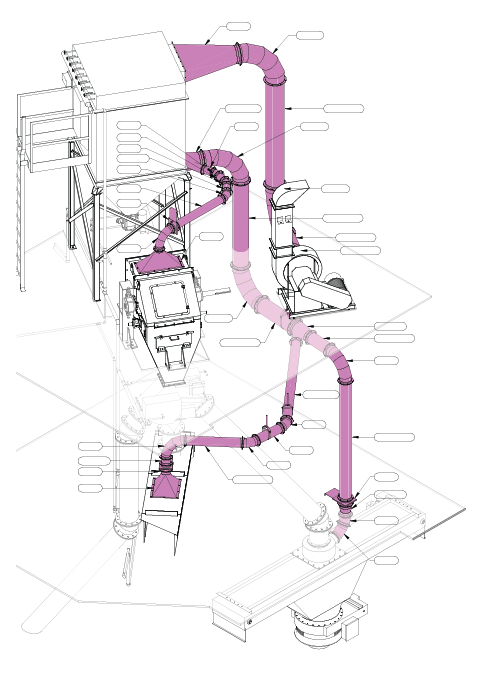

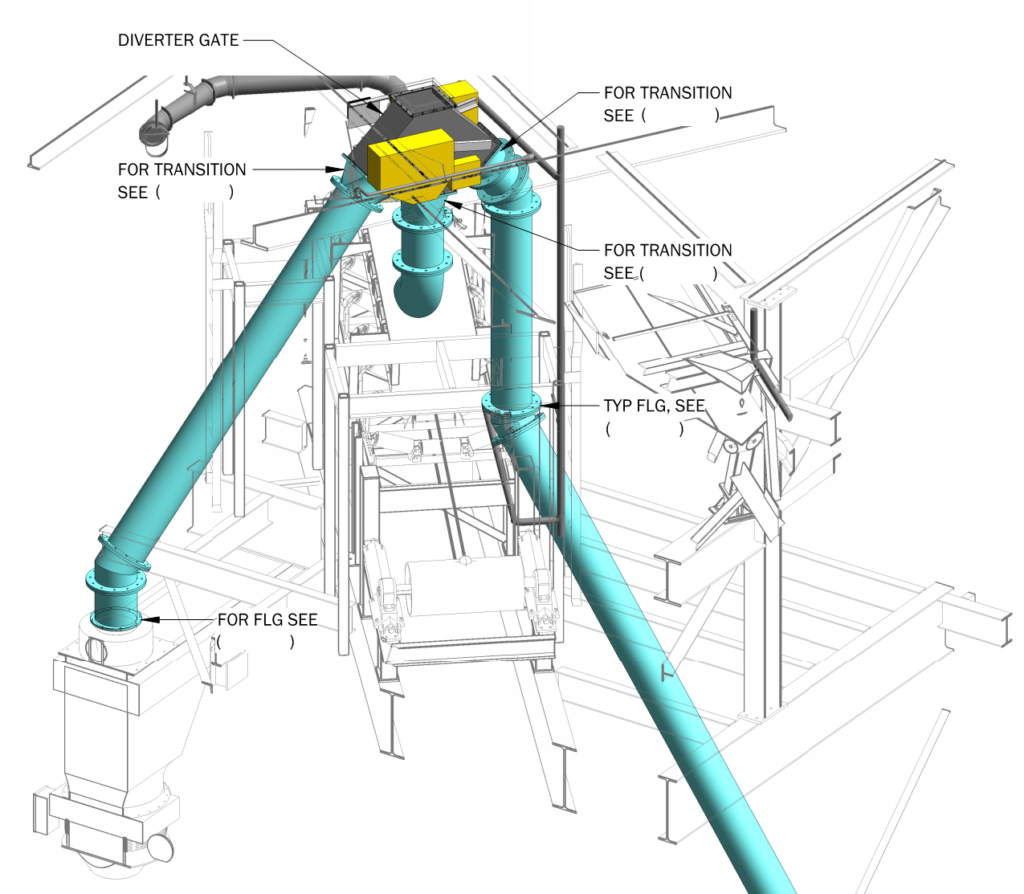

NEW DUST COLLECTION SYSTEMS

Dust collection systems can be as simple as a single collector serving one piece of equipment, or an elaborate centralized system with many connection points. In any case we can start you off on the right path and guide you all the way to the finish line. Here are some typical dust collection systems we enjoy designing:

- Conveyor transfer points

- Equipment pickup points

- Rail/Truck dump facilities

- Crushers and vibrating screens

- Rotary dryers

- Custom hoods

- Dry baghouses

- Wet collectors

- Venturi scrubbers

- Custom ductwork and supports

- Exhaust stacks

- Dust suppression

- Dry fog

We can complete your system by also designing:

- Access platforms

- Booster pumps

- Effluent / sump pumps

- Duct support structures

- Exhaust stack supports/towers

- Process and effluent piping

EXISTING SYSTEMS

Too often dust collection systems have been retrofit for added or removed equipment. This changes the dynamics of the duct system causing air velocities to be too high or too low in some areas. When velocities are too low, material can drop out of the air-stream and eventually buildup and create plugging issues and nuisance cleaning of the ducts. Re-handling this material drives up operating costs.

When velocities are too high, abrasive materials can wear holes in the ductwork. Excessive velocities also require the fan to use more energy than necessary to transport the captured dust. You may not need a completely new dust collection system. Sometimes replacing some of the duct work with the correct size will do the trick. Let us take a look and see if we can save you money.

EVALUATIONS AND BALANCING

For an “out-of-whack” dust collection system we can help by providing the following services:

- System evaluations

- System balancing

- Airflow measurements including static pressure, duct velocity and CFM

With our evaluation we will provide a schematic of your system with the duct velocities in each branch. We will provide recommendations on how you can improve your dust collection system to reduce dust, save energy and reduce labor costs from cleanup.

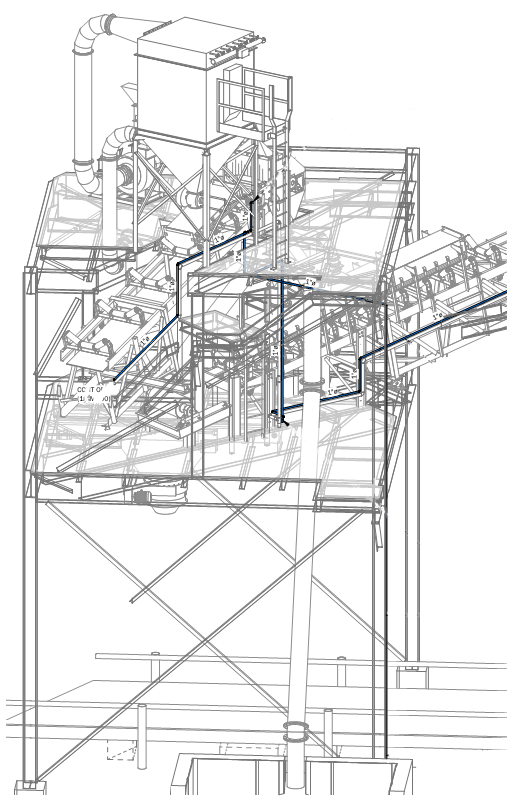

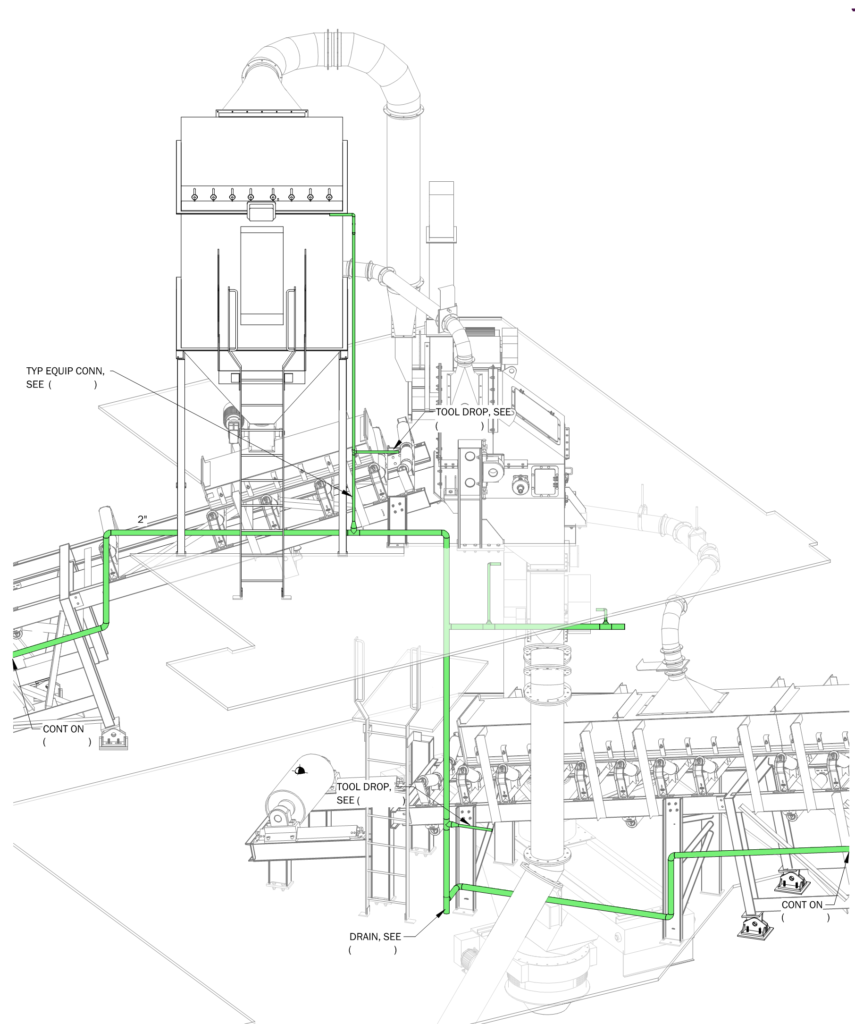

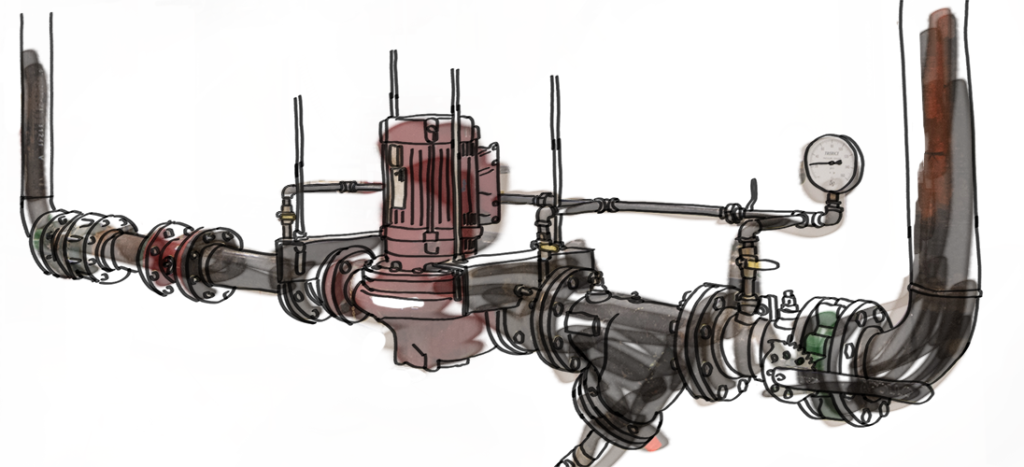

PIPING

Piping is an integral part of many facilities and processes. We have years of experience and hundreds of piping projects under our belts. We are experienced with everything from process piping, steam, chilled water, slurries and wash-down water systems that run for miles up and down conveyor belts. We can keep it simple from single line schematic layouts to fully modeled pipes with seismic bracing and supports depending on your project needs.

ENGINEERING AND DESIGN

We engineer systems that appropriately handle the fluid you are transporting. Engineering includes flow and pressure calculations, material selection, pump sizing and selection, supports, and inline equipment. We start with a process flow diagram or a P&ID. Our designs target proper fluid velocities and minimize friction losses to lower energy consumption and maximize the life of the system.

Our designs encompass equipment selection, tank and pump design, and any structural supports, access platforms or foundations needed to deliver a complete piping system. Pipe thickness, valve selection, corrosion allowance, cleanouts, system draining, and pipe stress are all factors that influence the design and layout of a piping system.

Below is a list of some of the types of piping systems we design and services that we offer:

- Process

- Chemical

- Effluent / drain

- Scrubber systems

- Molten salt

- Steam piping

- Trench drain systems

- Sand-oil-water separators and sampling

- Reverse osmosis (RO)

- Brine solutions

- Automatic washdown systems

- Cooling tower

- Open and closed loop systems

- Abrasive and viscous slurry

- Culinary water

- Natural gas

- Washdown water

- Compressed air / plant air

- Boiler and chiller piping

- Sanitary sewer and venting

- Vegetable oil

- Dust suppression and dry fog

- Caesar II Pipe stress analysis

- Vibration analysis

- Thermal expansion

- Seismic bracing

UPGRADES AND RETROFITS

We have many years of practical experience in the field and know the importance of minimizing down time during a retrofit or upgrade. Let us take a look and see what improvements can be made, and gather input from the maintenance and operations team. You know your process better than anyone. Your ideas and our collaboration produce ingenious solutions. We are simply the best at making those ingenious solutions a reality.

Let’s not make this hard!

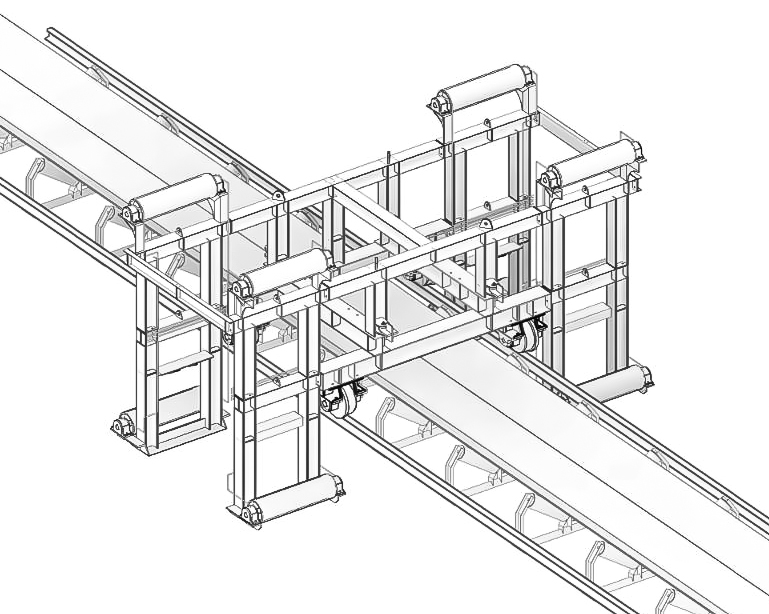

EQUIPMENT INTEGRATION & SPECIFICATION

Process equipment is the heart of a material handling system when beneficiating your product. Whether you are installing a new process or upgrading an existing process, that equipment will need to be integrated into your process. The equipment will likely need a support structure, chutework on the feed side and discharge of your new equipment as well as electrical and possibly compressed air, dust collection or an exhaust gas system. An existing process may require modifications to your structure, safety guarding or other ancillary systems. We typically start with a General Arrangement drawing with the proposed piece of equipment in place. At this stage we account for how the equipment is fed and how it will discharge downstream. We also consider construction, maintenance and safety of the equipment. Any ancillary systems are also included as required. Once the General Arrangement is established, we work with the client or the equipment vendor directly to ensure the equipment needs are met and that we have sufficient drawings to design for the equipment. Detailed engineering can then be performed by our structural, mechanical and electrical engineers as needed. We can also integrate or design the transport equipment between each piece of process equipment. This may include belt conveyors, feeders, bucket elevators or gravity chutes.

Below is a list of some of the process equipment we have had experience with:

- Vibrating screens

- Rotary dryers

- Kilns

- Crushers

- Sampling systems

- Fluid bed dryers

- Cooling columns

- Mixers

- Scrubbers

- Cyclones

- Tanks

- Bucket elevators compactors

- Delumpers

- Granulators

- Pelletizer

- Feeders

- Conveyors

- Trippers

- Silos

- Bins

- Hoppers

- Radial stackers

- Loading spouts

- Mills

- Centrifuges

- Loading systems

- Reclaim systems

- Dewatering Systems

- Sizers

- Breakers

- Filter presses

- Tanks

HVAC

We have done hundreds of HVAC projects over the years. We specialize in HVAC engineering, design, and equipment specifications for industrial, manufacturing and warehouse facilities. We design everything from new complex systems to small retrofit projects, and can provide systems for human comfort as well as machines. Every facility has specific requirements that we keep in mind as we design.

Below are some of the typical systems we design:

- Roof top units

- Split dx systems

- Chillers

- Boilers

- Fan coils

- Energy recovery systems

- Heat pumps

- Infrared heaters

- Steam, gas, and electric heaters

- Explosion proof equipment for dust/gas environments

- Ventilation fans

- Exhaust systems

- High volume low speed fans (HVLS)

- Dust collection systems

- Drying systems

- Filtration systems